Motorcycle Ramps

Available in 18 days, delivery time 2 - 3 days

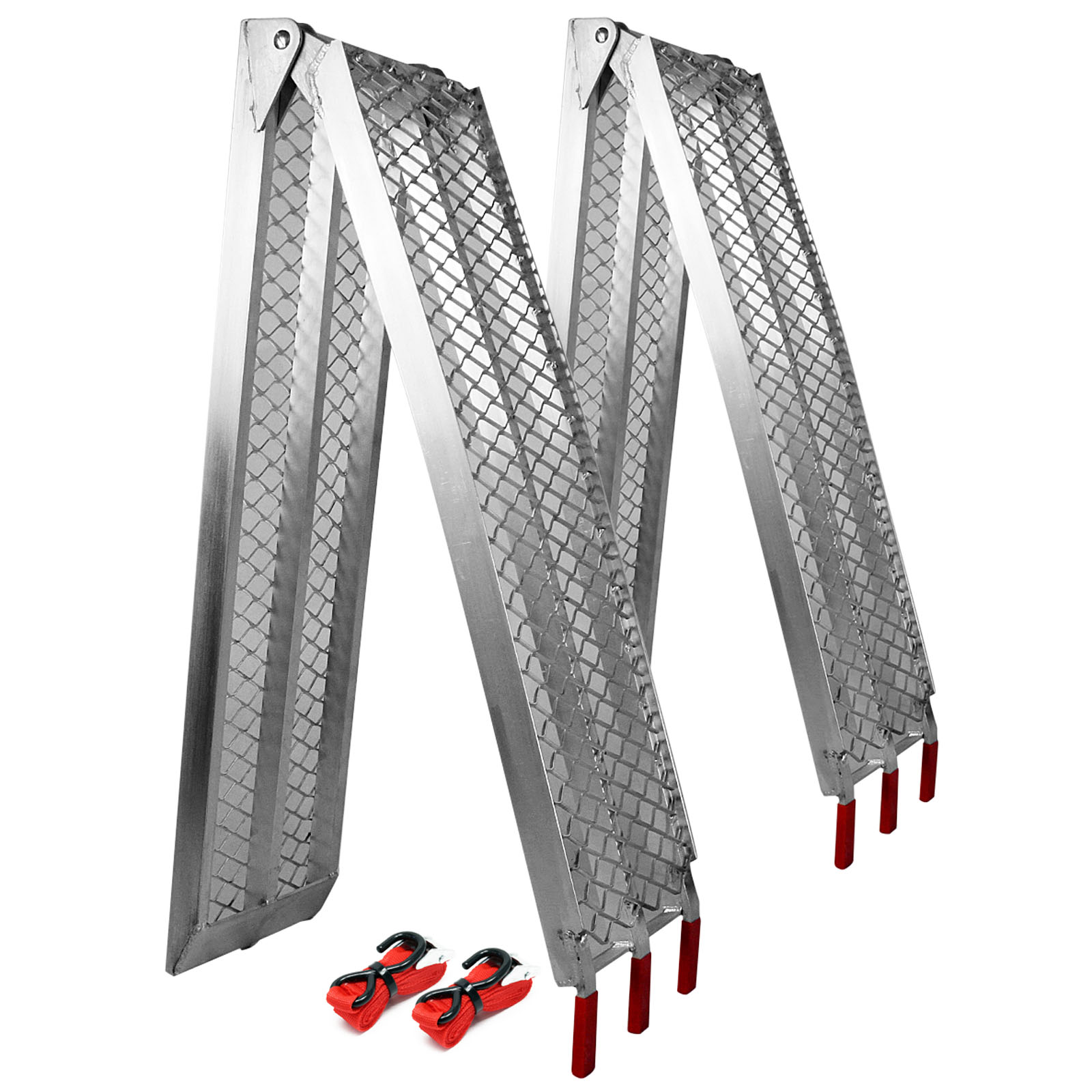

• Space-saving storage

• Foldable

• Length: 310 cm

• max. loading capacity: 540 kg

• Including safety belt

Available, delivery time: 2 - 3 days

• Folding

• Max. load 340 kg

• For tyre width up to 280 mm

• Length: 220 cm

Available, delivery time: 2 - 3 days

• Space-saving storage, foldable

• Length: 226 cm

• Max. loading capacity: 340 kg

• Including safety belt

Available, delivery time: 2 - 3 days

• Foldable

• Length: 228 cm

• Max. load capacity: 1360 kg

Available, delivery time: 2 - 3 days

• Space-saving storage

• Foldable

• Length: 226 cm, Width: 30,5 cm

• max. loading capacity: 340 kg

• Including safety belt

Available, delivery time: 2 - 3 days

• Space-saving storage

• Foldable

• Length: 228 cm

• max. loading capacity 680 kg

• Including safety belt

Available in 18 days, delivery time 2 - 3 days

• Foldable

• Length: 310 cm

• Max. load capacity: 1080 kg

Available, delivery time: 2 - 3 days

• Foldable

• Length: 226 cm

• Max. load capacity: 800 kg

Available, delivery time: 2 - 3 days

• Dimension: 160 x 22,5 cm

• Galvanized steel

• To be loaded up to 400 kg at a maximum

• Corrugated surface

• Space-saving storage

Available, delivery time: 2 - 3 days

• Space-saving storage

• Length: 163 cm

• Capacity load max. 180 kg

Available, delivery time: 2 - 3 days

• Foldable for space-saving storage

• With a length of 215 cm

• With a maximum loading capacity of 680 kg

• For scooter, ATV, quad, motorbike etc.

Available, delivery time: 2 - 3 days

• Space-saving storage

• Foldable

• Length: 226 cm

• Max. loading capacity: 340 kg

• Including safety belt

Available, delivery time: 2 - 3 days

• Foldable

• Length: 226 cm

• Max. load capacity: 680 kg

Available, delivery time: 2 - 3 days

• Space-saving storage

• Foldable

• Length: 226 cm

• max. loading capacity: 410 kg

• Including safety belt

Available, delivery time: 2 - 3 days

• Space-saving storage

• Foldable

• Length: 182 cm

• Capacity load max. 200 kg

Available, delivery time: 2 - 3 days

• Foldable for space-saving storage

• With a length of 215 cm

• With a maximum loading capacity of 340kg

• Scope of delivery includes a safety belt

Available, delivery time: 2 - 3 days

• Space-saving storage

• Length: 161 cm

• Capacity load max. 2025 kg

Available, delivery time: 2 - 3 days

• Dimension: 160 x 22,5 x 4,5 cm

• Galvanized steel

• To be loaded up to 400 kg at a maximum

• Corrugated surface

• Space-saving storage

Available, delivery time: 2 - 3 days

• Foldable

• Length: 226 cm

• Max. load capacity: 680 kg

Available, delivery time: 2 - 3 days

• 2 stable steel ramps with non-skid profile

• Threefoldly folding ramps for easy transport

• 340 kg loading capacity per ramp or 680 kg per pair

• For motorbikes, quad bikes, ATVs, ride-on mowers, etc.

Available, delivery time: 2 - 3 days

• Space-saving storage

• Length: 192 cm

• Capacity load max. 182 kg

Available, delivery time: 2 - 3 days

• Space-saving storage

• Length 161 cm

• Max. load capacity: 4050 kg

Available, delivery time: 2 - 3 days

• Dimensions folded: 1170 x 290 x 140 mm

• Dimensions open: 2230 x 290 x 100 mm

• Ramp width: 275 mm

• Max. loading capacity: 340 kg

Available, delivery time: 2 - 3 days

• Foldable

• Length: 226 cm

• Max. load capacity: 1360 kg

Motorcycle Ramps

The Comprehensive Guide for Safe and Efficient Loading

Ramps play a crucial role in numerous areas—from logistics and mobility assistance to leisure activities. They enable the safe and efficient loading of vehicles, machinery, and other heavy items. Our range offers a wide selection of ramps tailored to different needs and applications.

Versatile Applications

Ramps are indispensable for loading motorcycles, ATVs, construction equipment, and much more. They facilitate access to trailers, storage areas, and overcoming height differences. Our product line includes:

Loading ramps: Ideal for cars, motorcycles, and light commercial vehicles.

Heavy-duty ramps: Sturdy solutions for heavy loads and construction equipment.

Motorcycle ramps: Specifically designed for easy loading of two-wheelers.

Foldable ramps: Convenient, space-saving options for mobile use.

Choosing the Right Ramp

Which loading ramp do I need?

Selecting the right loading ramp depends on various factors. Here are some key factors you should consider to find the suitable ramp for your needs:

Purpose: Consider what you will primarily use the ramp for. Do you need it for a motorcycle, a car, a wheelchair, or heavy machinery? The type of item being loaded significantly determines the kind of ramp you need.

Load capacity: Load capacity is one of the most critical factors. The ramp must be able to safely carry the weight of the item being loaded. Consider the total weight and choose a ramp with a corresponding load limit to ensure maximum safety.

Material: Ramps are commonly made of aluminum or steel. Aluminum ramps are lighter and therefore easier to transport and handle, while steel ramps are typically heavier but more robust and often suitable for higher loads.

Size and length: The size and length of the ramp should be chosen to allow safe ascent and descent while being compatible with spatial conditions, such as the height of the vehicle or the loading edge. A longer ramp provides a gentler angle, making loading easier.

Mobility and storage: If you need the ramp frequently at different locations, a foldable or telescopic ramp that is easy to transport and store might be the best choice.

Incline: A gentler angle (lower incline) is easier to navigate, especially for heavy or motorized vehicles. The ideal incline angle depends on usage; generally, the incline should be kept as low as possible to facilitate use.

Surface: A non-slip surface is essential for safety, especially in wet or dirty conditions. Ensure the ramp has a suitable coating or texture that allows safe use.

Safety features: Additional features like side edges, safety straps, or end hooks can increase safety when using the ramp.

By considering these factors, you can select the loading ramp that best suits your requirements. Reading reviews and consulting professionals, if necessary, can also be helpful to ensure the ramp is suitable for your specific needs.

How to Drive onto a Loading Ramp?

Safely driving onto a ramp requires preparation and care to avoid accidents and damage. Here are some steps and tips on how to drive onto a loading ramp:

1. Correctly position and secure the ramp: Ensure the ramp is firmly and securely attached to the loading area or vehicle. The ramp should not slip or move when loaded. Use all available securing devices like hooks, loops, or latches that come with the ramp.

2. Check the surroundings: Ensure the area around the ramp is clear of obstacles and there is enough space for maneuvering. Make sure the ground is stable and level.

3. Drive up slowly: Approach the ramp slowly and carefully. Sudden movements or driving up too fast can cause the ramp to slip or the vehicle to get damaged. For motorized vehicles, use a low gear to maintain control.

4. Stay centered: Keep the vehicle or item being loaded centered on the ramp. This helps distribute the weight evenly and ensures stability throughout the process.

5. Maintain a steady speed: Keep a constant, low speed while driving up and over the ramp. Avoid abrupt acceleration or braking on the ramp.

6. Involve a helper: For larger vehicles or if unsure, ask a second person to give you instructions or watch you as you drive onto the ramp. This can be especially helpful to ensure you stay centered and do not overload the ramp.

7. After driving up: Once the vehicle or item is fully on the desired surface, ensure it is safely parked and, if necessary, secured before removing the ramp or leaving the vehicle.

How High Should a Loading Ramp Be?

The height of a loading ramp itself is not the critical factor in selection; instead, focus on the length of the ramp and the incline angle required to overcome a specific height to which the vehicle or item should be led up or down. The height you wish to overcome with the ramp—for example, the height of a trailer's loading area or a step to a platform—determines how long the ramp needs to be to ensure a safe and feasible incline angle.

A gentler incline angle is preferred as it facilitates loading and minimizes the risk of vehicles, especially those with low ground clearance, bottoming out, or individuals using the ramp to trip or fall. A generally recommended incline angle is a maximum of 15 to 20 degrees for automotive use. For wheelchairs and mobility aids, accessibility guidelines require much flatter angles, typically no more than 8 to 10 degrees.

Calculating the Required Length of the Loading Ramp:

To determine the necessary length of the ramp for a given height at a safe incline angle, the following formula can be helpful:

Length of the ramp = Height to be overcome divided by sin (incline angle)

The incline angle should be given in radians when performing the calculation. For everyday purposes and easy handling, there are online calculators and tables that directly provide the ramp length based on the height and desired incline angle.

Example:

For a height of 60 cm (0.6 m) and a desired incline angle of 15 degrees (which corresponds to a sine value of about 0.2588), the necessary length of the ramp would be:

Length = 0.6 m divided by 0.2588 ≈ 2.32 m

This means that for an overcoming height of 60 cm and an incline angle of 15 degrees, a ramp with a length of about 2.32 meters would be needed.

It is important to always consider the specific requirements and the safety of the users. In case of uncertainties, especially with ramps for persons with disabilities or very high loads, it is advisable to consult a professional or rely on standardized solutions that comply with common safety requirements.

How Heavy is a Loading Ramp?

The weight of a loading ramp depends on various factors, such as the material used, the size of the ramp, as well as its load capacity and design. Here are some general guidelines to give you an idea of the weight of different types of loading ramps:

Aluminum Ramps:

Aluminum is a popular material for loading ramps because it is light yet very stable. A simple aluminum loading ramp for personal use, such as for motorcycles or small ATVs, can weigh between 5 kg and 15 kg. Larger aluminum ramps for heavy vehicles or equipment can weigh between 15 kg and 30 kg, depending on length and load capacity.

Steel Ramps:

Steel is more robust than aluminum and is often used for heavy-duty loading ramps. However, this leads to a higher weight. Small to medium-sized steel ramps can weigh between 10 kg and 25 kg, while larger heavy-duty steel ramps can weigh 30 kg to over 50 kg, especially if they are designed for commercial use or very heavy loads.

Foldable Ramps:

Foldable ramps offer the advantage of portability and easy storage. They are often designed to be lighter to facilitate transport. Small foldable ramps can weigh less than 10 kg, while larger models, depending on the material and construction, can weigh up to 20 kg or more.

Telescopic Ramps:

Telescopic ramps, which can be extended for flexible length adjustment, vary in weight depending on the material, maximum length, and load capacity. They can range from about 7 kg for light, portable models to over 20 kg for more robust versions.

It is important to consider the weight of the ramp in relation to its load capacity and the necessity of transport. For applications where the ramp needs to be moved regularly, a lighter aluminum or a foldable ramp might be the better choice. For stationary or heavy-duty applications, heavier steel ramps might be more appropriate. Product specifications and manufacturer details should always be consulted to determine the exact weight and suitability of a ramp for your specific needs.

How Do You Secure a Loading Ramp?

Securing a loading ramp is crucial for safety when loading vehicles or other loads. Here are general guidelines on how to securely fasten a loading ramp:

1. Check the Ground:

Ensure the ground on which the ramp is placed is firm and level. Irregularities or a yielding ground can compromise the stability of the ramp.

2. Correct Positioning:

The ramp must be positioned to offer a flat and safe angle to the loading target. Ensure the end of the ramp firmly lies against the loading area or the edge of the loading target to ensure safe crossing.

3. Use Safety Devices:

Many loading ramps come with safety devices such as hooks, loops, or clamps that can lock onto the loading edge or wrap around it. Ensure these safety devices are correctly attached and tightened to prevent the ramp from slipping.

4. Consider Weight Distribution:

Distribute the weight evenly on the ramp. If using multiple ramps, ensure each ramp is evenly loaded to prevent tipping or shifting.

5. Use Non-slip Pads:

If the ramp does not have integrated safety devices or additional stability is required, non-slip pads or mats can be placed under the contact points of the ramp to minimize the risk of slipping.

6. Check Before Use:

Before using the ramp, check again if it is firmly and securely fastened. A final check can minimize potential risks.

7. Additional Securing:

Depending on the type of ramp and the loading target, additional securing measures such as tension straps or chains can be used to fasten the ramp to the vehicle or loading platform.

8. Follow Manufacturer’s Instructions:

Always follow the specific instructions and recommendations of the manufacturer for securing the ramp. Manufacturers often provide detailed instructions for the safe attachment and use of their products.

By following these steps, you can enhance safety when using loading ramps and minimize the risk of accidents or damage to loads and equipment.

How Steep Can a Loading Ramp Be?

The optimal steepness of a loading ramp depends on its application and what is being loaded. In general, the flatter the angle, the safer and easier the loading, especially for heavy, unwieldy loads or vehicles with low ground clearance.

For vehicles, a maximum incline angle of 15 to 20 degrees is often recommended. At this incline, most vehicles, including sports cars with low ground clearance, can safely drive up and down without damaging the underside of the vehicle or the exhaust.

For wheelchair ramps, specific guidelines aim to maximize accessibility. For example, the ADA (Americans with Disabilities Act) recommends an incline angle of 1:12 for wheelchair ramps, meaning the ramp should extend 12 inches in length for every inch of height. This corresponds to an incline angle of about 4.8 degrees.

For loading construction machinery or heavy equipment, it may be necessary to use even flatter angles to ensure safety during loading and to ensure that the machinery does not tip over.

Safe Loading with the Right Ramp

The right ramp can make a difference in safety, efficiency, and comfort. Our diverse range of ramps is tailored to our customers' needs and offers the right solution for every requirement. Whether for transporting heavy machinery, loading motorcycles, or ensuring accessibility – our ramps set new standards in quality and user-friendliness.