Bending Machines

Available, delivery time: 2 - 3 days

• Suitable for thin walled, soft pipes

• For flexible aluminium, copper & plastic pipes

• Pressing bit 14 – 32 mm

• For max. 90° angles

Available, delivery time: 2 - 3 days

• With six different bending dies

• For bending angles of up to 90°

• For pipes with 6.35–25.4 mm (¼″–1″) diameter

• For tubes 1–3.5 mm material thickness

Available, delivery time: 2 - 3 days

• Maximal metal sheet thickness: 1.2 mm

• Maximal insertion depth of metal sheets: 440 mm

• 6 pairs of shafts with various profile rolls

• Operated via hand crank

Available in 20 days, delivery time 2 - 3 days

• Pressings with 21,3 mm–60,3 mm

• Dimensions total 630 x 540 x 170 mm

• For vertical use

• Weight approx. 30 kg

Available in 40 days, delivery time 2 - 3 days

• pressing force:

• max. 1t (9.8067 kn)

• base plate: Ø 100 mm

• for various pressing tasks

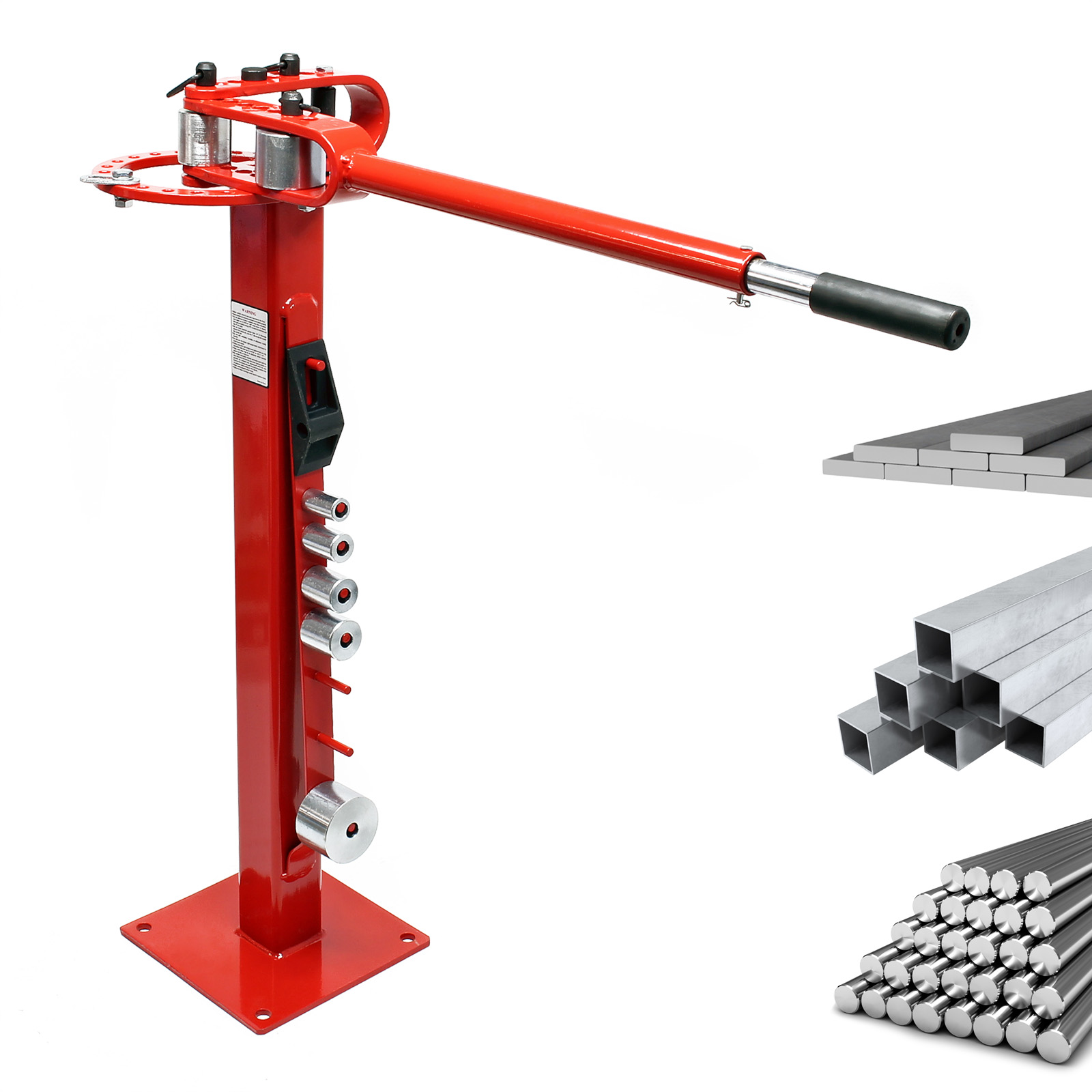

Available, delivery time: 2 - 3 days

• For construction steel, flat steel, round steel and square steel

• Base plate with pre-drilled holes

• Various bending molds included

• Ideal for hobby or professional occasions

Available, delivery time: 2 - 3 days

• Shaping, planing, and hardening

• For metal working

• E.g. for treating bodywork

• Made from steel

Available, delivery time: 2 - 3 days

• High quality

• multi-purpose

• snap-together design

• practical carry case and attachments

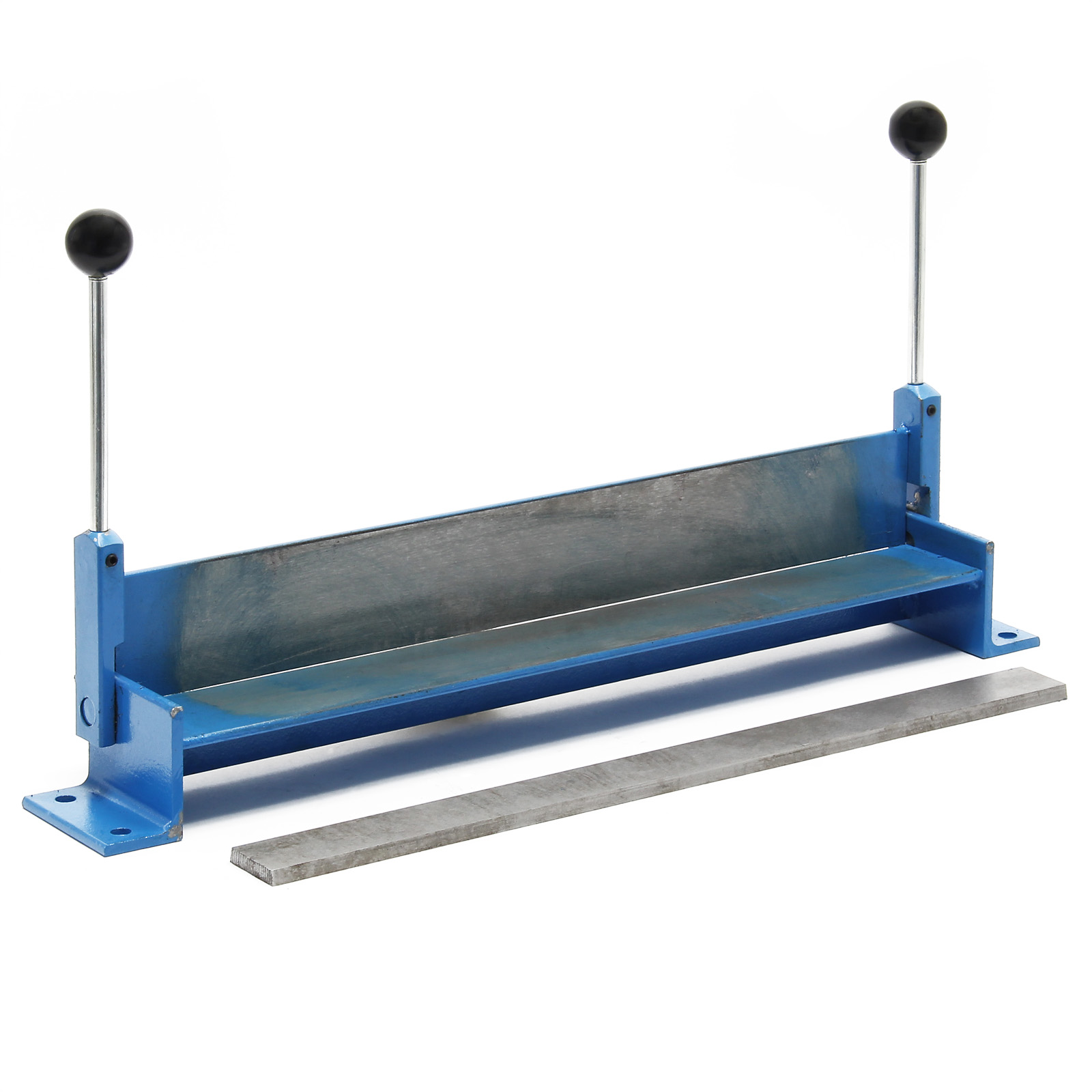

Available in 47 days, delivery time 2 - 3 days

• Mountable to tables

• Precise results

• Adjustable bending radius

• Easy to operate

Available in 40 days, delivery time 2 - 3 days

• High quality

• Easy handling

• Precise results

• Universal application

Available, delivery time: 2 - 3 days

• Includes 8 dies made of cast iron

• Bending Angle up to 90°

• Bends all common tubes

• Weight: 63 kg

Available in 40 days, delivery time 2 - 3 days

• Can shrink and stretch metal sheets

• Folded steel sheets up to 1.2 mm

• Hand lever to transmit pressure

• Including tool equipment to stretch and shrink

Available, delivery time: 2 - 3 days

• Suitable for cold and hot bending

• 120 degree scale

• Weight including handle: 26.5 kg

Available in 57 days, delivery time 2 - 3 days

• High quality

• Simple handling

• Precise results

• Max. bending angle: 135°

Available, delivery time: 2 - 3 days

• Maximal metal sheet thickness: 1.2 mm

• Maximal insertion depth of metal sheets: 440 mm

• 6 pairs of shafts with various tread types

• Can be mounted to the floor

Available, delivery time: 2 - 3 days

• High quality

• Easy to handle

• High precision

• Versatile

Available, delivery time: 2 - 3 days

• pressing force:

• max. 2t (19.6133 kn)

• base plate: Ø 170 mm

• for various pressing tasks

Available, delivery time: 2 - 3 days

• 8 puller varities possible with reconstruction

• reconstruction as 2- and 3-jaws-puller

• high quality production

Available, delivery time: 2 - 3 days

• For flat steel, round steel, construction steel, and square steel

• Ideal for radius bending up to 2000 mm

• Base plate with pre-drilled holes

• Various bending molds included

Available, delivery time: 2 - 3 days

• High quality

• Simple handling

• Precise results

• Max. bending angle: 135°

Available in 57 days, delivery time 2 - 3 days

• To form cylinders, pipes and curvatures

• Can straighten out metal sheets

• Max. sheet thickness of 2.5 mm

• Max. 320 mm width

Available, delivery time: 2 - 3 days

• Original spare part

Available, delivery time: 2 - 3 days

• High quality

• Easy to handle

• High precision

• Versatile

Available, delivery time: 2 - 3 days

• For 30 mm Eyelet Tips

• Adjustable Pressing Pressure

• Material Cast Iron

• Weight approx. 3.39 kg