Clamps & Vices

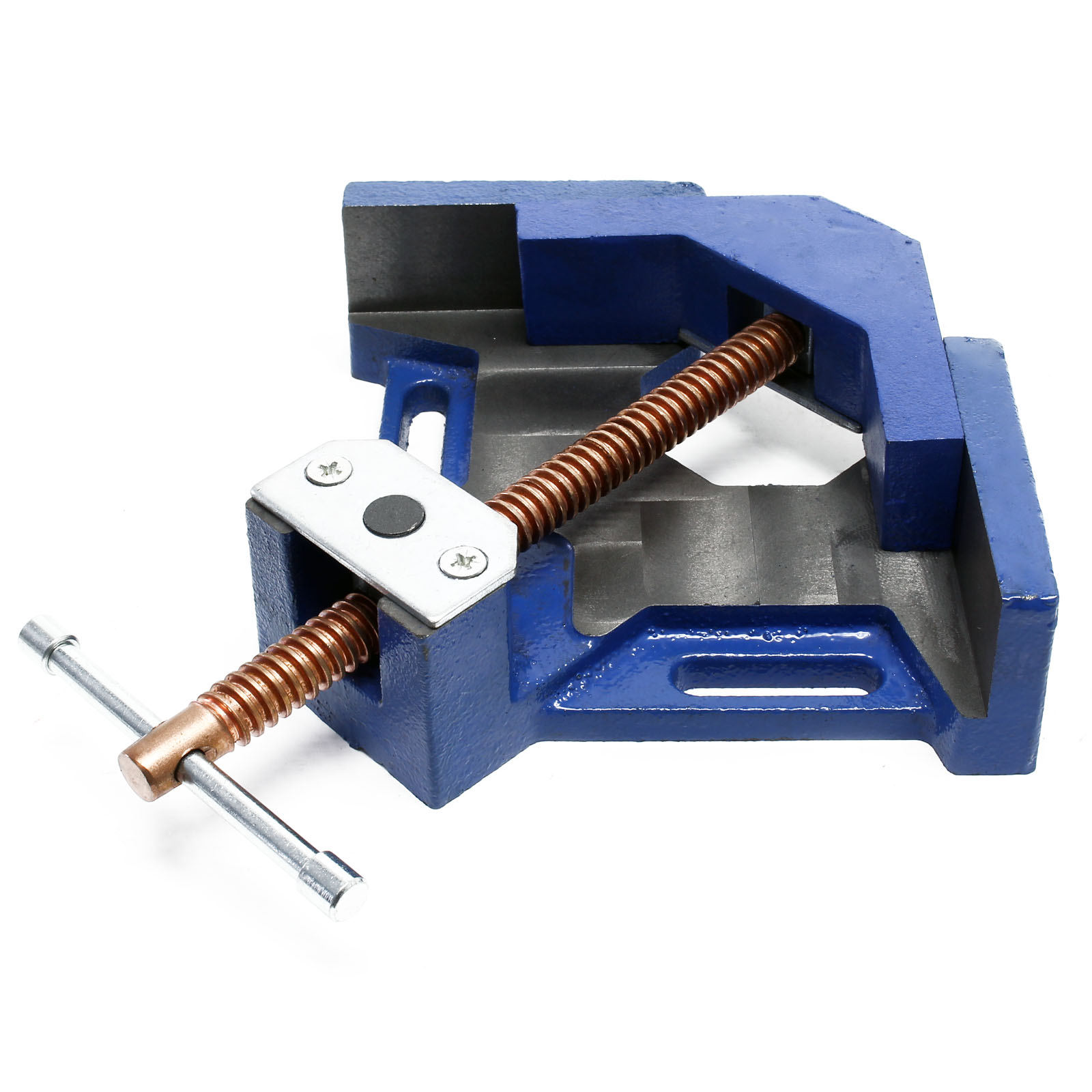

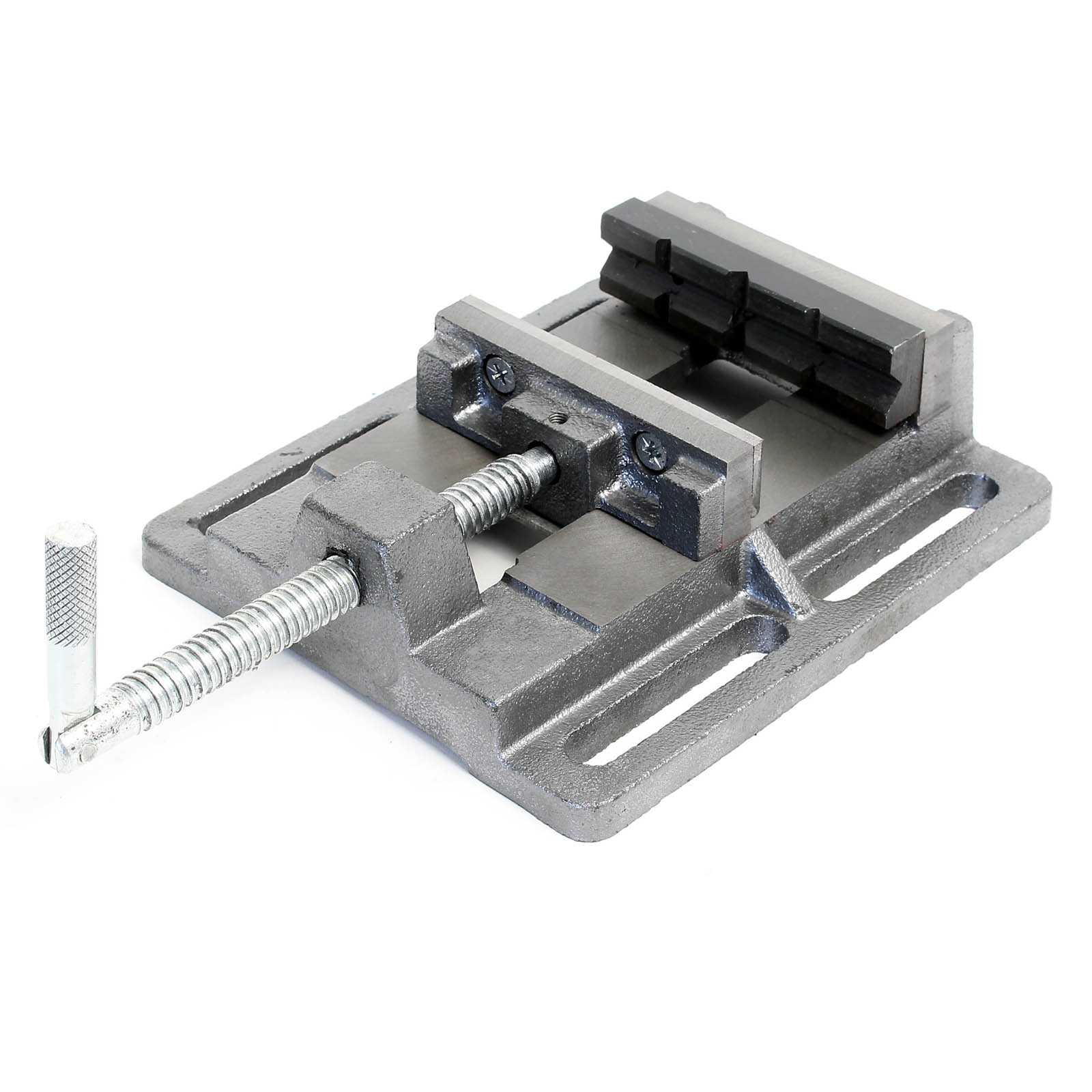

Available, delivery time: 2 - 3 days

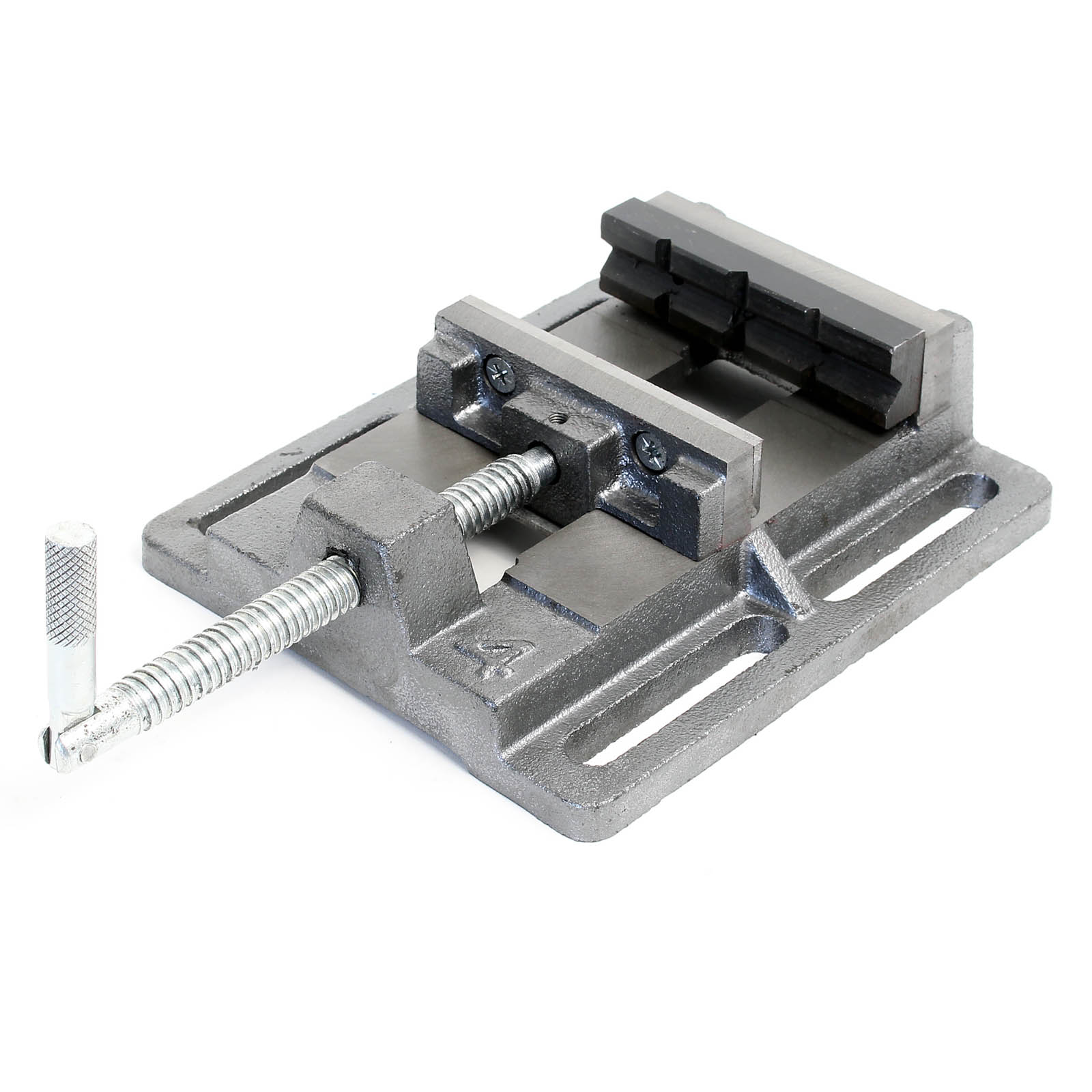

• Angular accuracy

• Jaw width 100 mm

• Maximum clamping depth 60 mm

• 4 kg

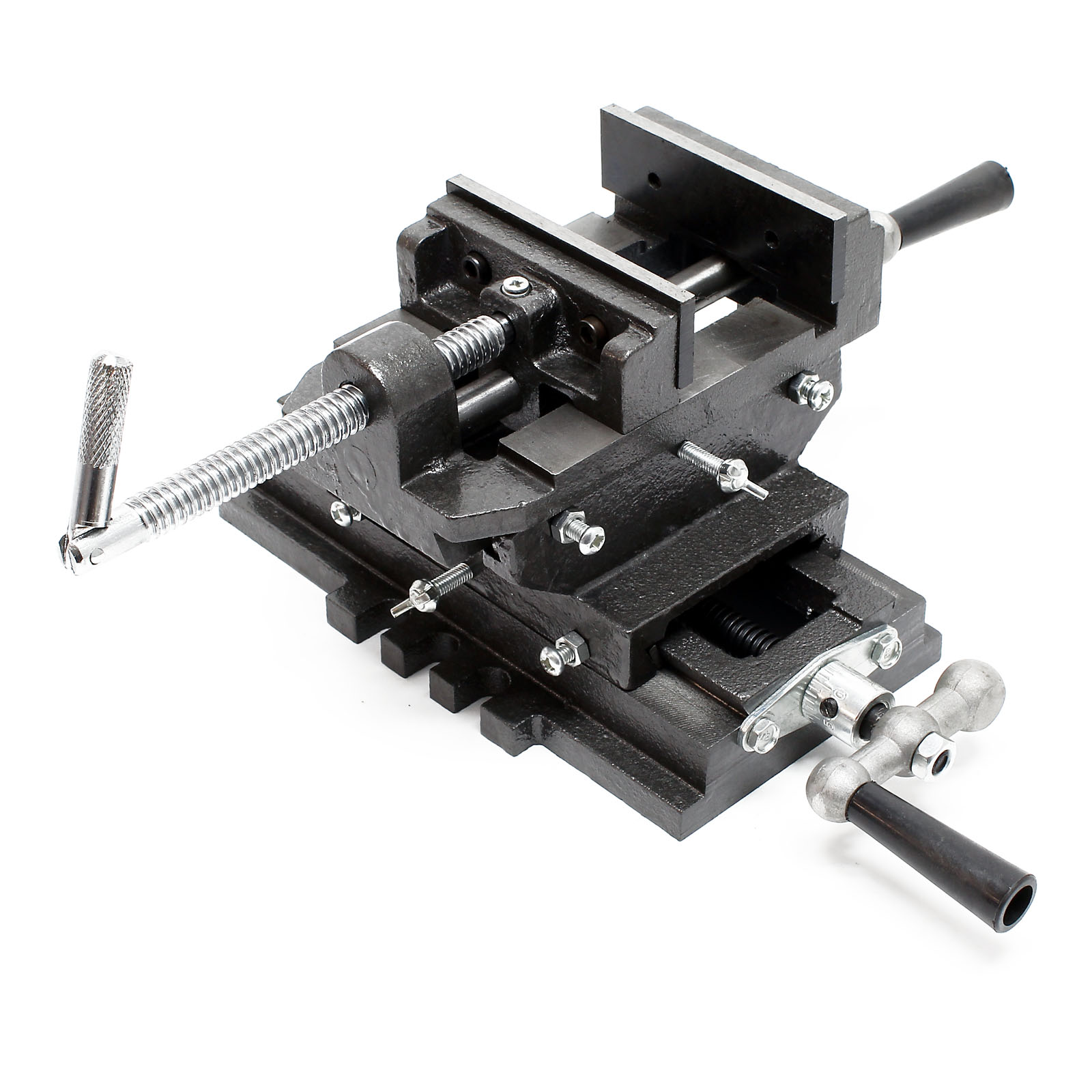

Available, delivery time: 2 - 3 days

• Jaw width 100 mm

• Span width 100 mm

• Clamping depth 37 mm

• Weight 7.5 kg

Available in 25 days, delivery time 2 - 3 days

• Capable of exact settings

• Jaw parallelism: <0,05 / 100 mm

• Jaw width: 100 mm

• With adjustable swivel

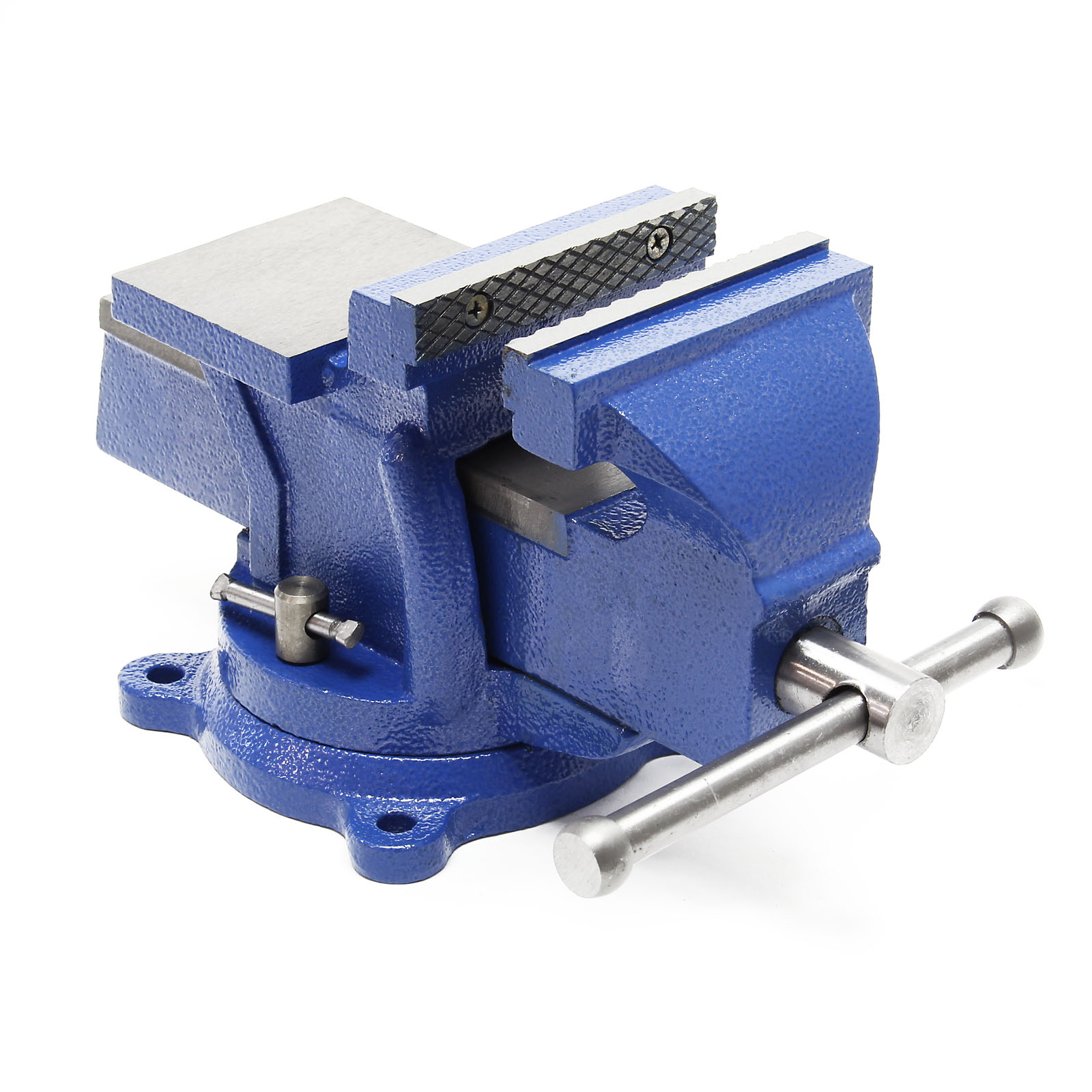

Available, delivery time: 2 - 3 days

• Angular accuracy

• Jaw width: 100 mm

• Maximum clamping depth: 75 mm

• Weight: 10 kg

Available, delivery time: 2 - 3 days

• Jaw width: 150 mm

• Jaw height: 26/30 mm

• Clamping range: 130 mm

• Weight: 6.4 kg

Available, delivery time: 2 - 3 days

• Jaw width: 100 mm

• Jaw height: 22/25 mm

• Clamping range: 80 mm

• Weight: 3 kg

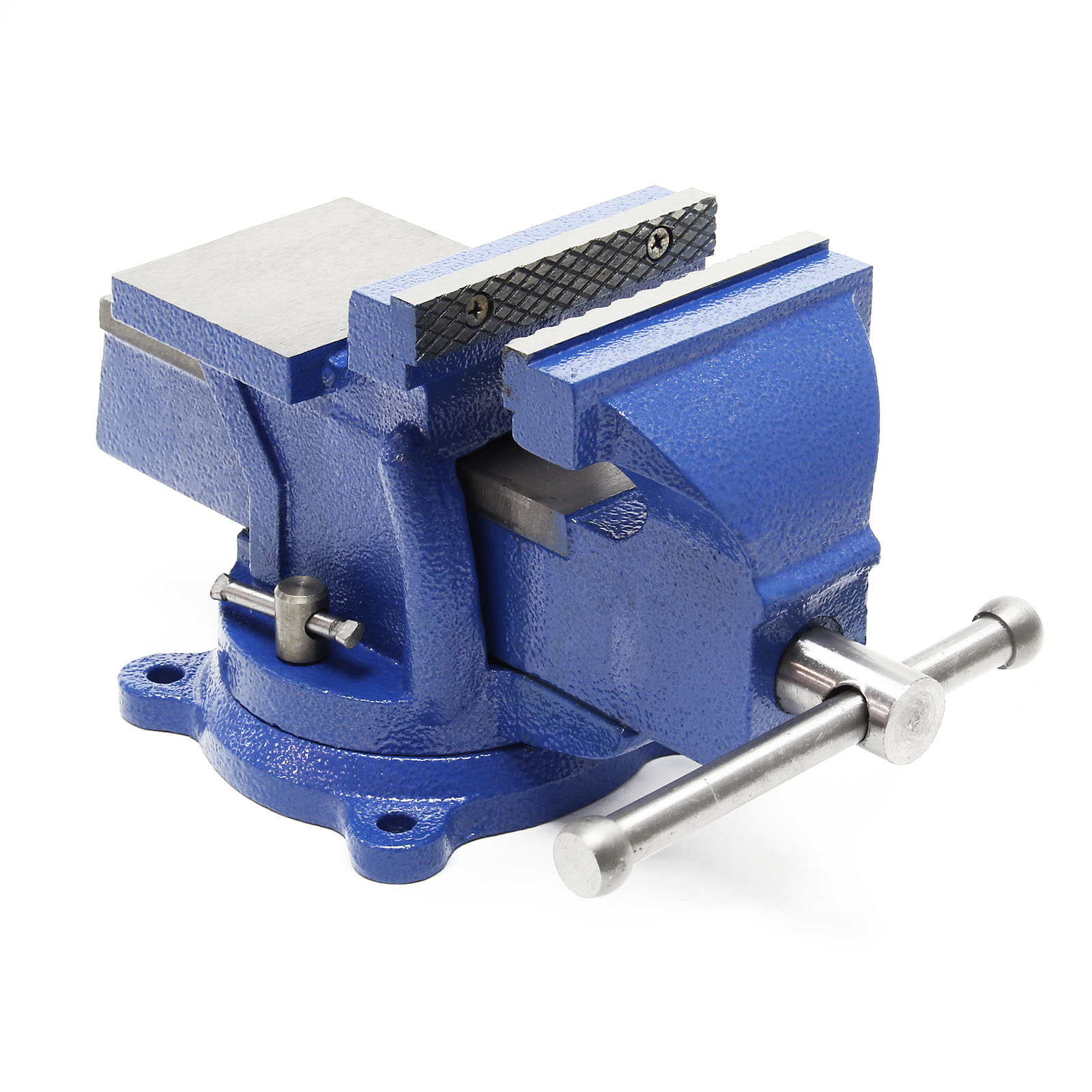

Available, delivery time: 2 - 3 days

• Width of clamping jaws 125 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

Available, delivery time: 2 - 3 days

• Jaw width: 75 mm

• Jaw height: 22/25 mm

• Clamping range: 46 mm

• Weight: 2 kg

Available, delivery time: 2 - 3 days

• Easy fixation

• Adjustable axes

• Jaw width: 75mm

• Jaw opening: 75mm

Available, delivery time: 2 - 3 days

• Jaw width: 200 mm

• Jaw height: 26/30 mm

• Clamping range: 185 mm

• Weight: 9 kg

Available, delivery time: 2 - 3 days

• Width of clamping jaws 150 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

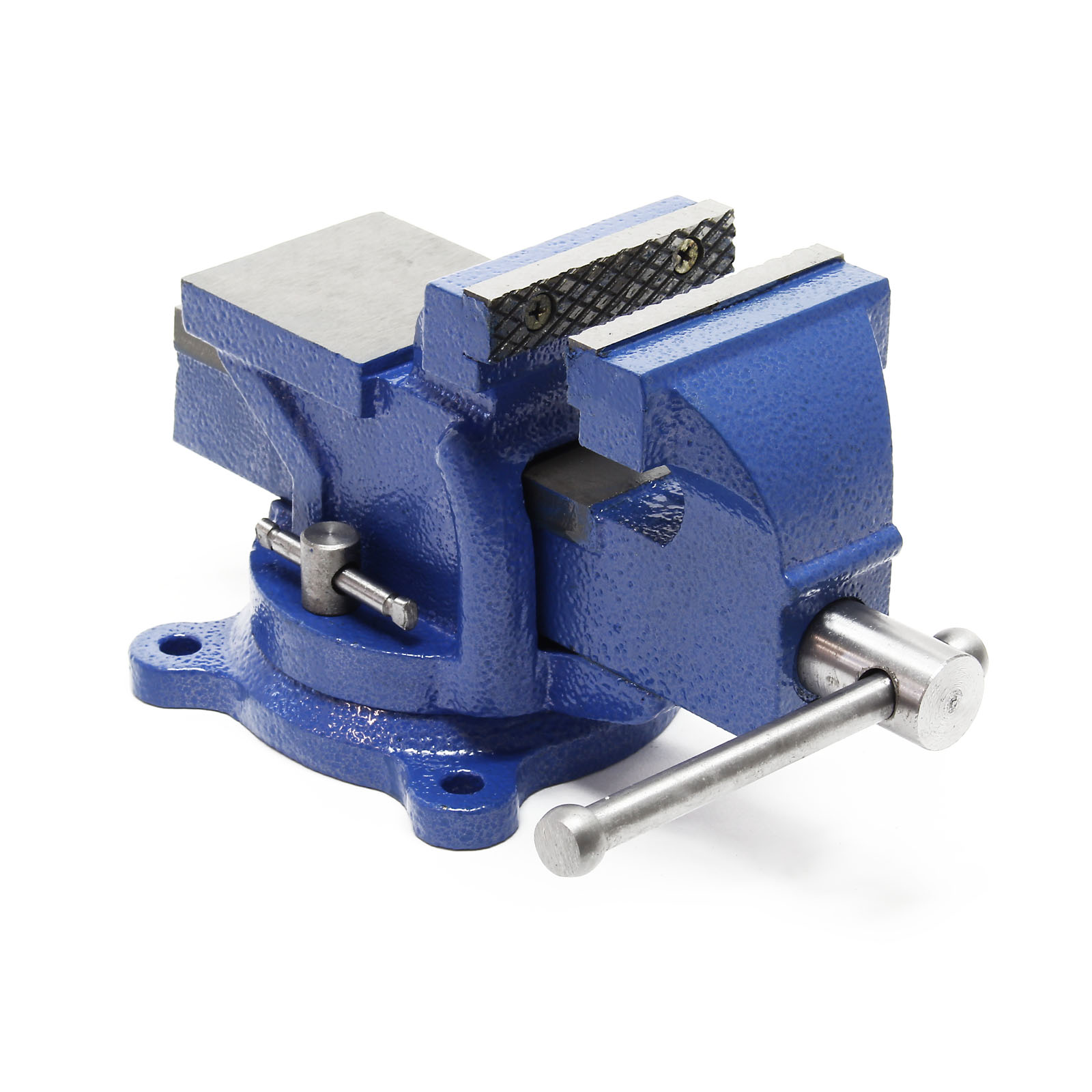

Available, delivery time: 2 - 3 days

• Width of clamping jaws 100 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

Available, delivery time: 2 - 3 days

• Easy fixation

• Adjustable axes

• Jaw width: 150mm

• Jaw opening: 150mm

Available, delivery time: 2 - 3 days

• Jaw width: 125 mm

• Jaw height: 26/30 mm

• Clamping range: 95 mm

• Weight: 5 kg

Available, delivery time: 2 - 3 days

• Jaw width: 75 mm

• Jaw height: 28 mm

• Jaw opening: 59 mm

• Weight: 2 kg

Available, delivery time: 2 - 3 days

• Angle spanner made of aluminium with steel shaft

• Adjustable to workpieces of different thickness

• Ergonomic and anti-slip plastic handle

• Suitable for wood, metal, glass, or plastic

Available, delivery time: 2 - 3 days

• Capable of exact settings

• Jaw concurrency <0,05 / 100 mm

• Jaw width: 100 mm

• Adjustable swivel joint

Available, delivery time: 2 - 3 days

• Width of clamping jaws 75 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

Available, delivery time: 2 - 3 days

• Jaw opening: max.110 mm

• Weight: 19kg

• Safe securing

• Rotatable 360 °

Available, delivery time: 2 - 3 days

• 360° swivelling

• Made of aluminium

• E.g., for modelling or fine mechanics

• Jaws: 78 mm

Available, delivery time: 2 - 3 days

• Width of clamping jaws 200 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

Available, delivery time: 2 - 3 days

• Width of clamping jaws 100 mm

• Can be attached to a workbench

• Suitable for machining long workpieces

• With anvil

Available, delivery time: 2 - 3 days

• Jaw width: 75 mm

• Jaw height: 28 mm

• Jaw opening: 100 mm

• Weight: 3 kg

Available, delivery time: 2 - 3 days

• Jaw opening: max.72mm

• Weight: 12kg

• Safe securing

• Rotatable 360 °