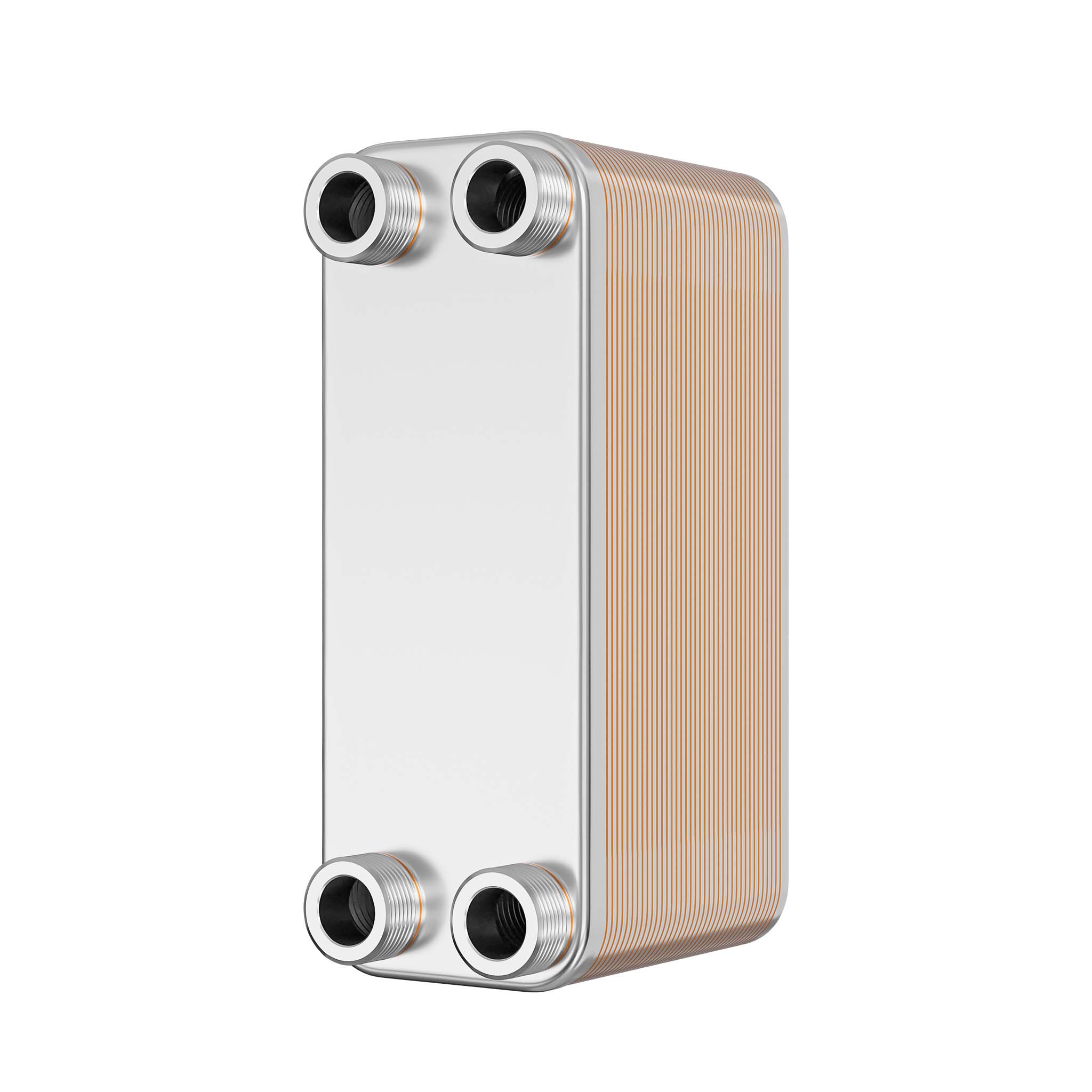

Heat Exchangers

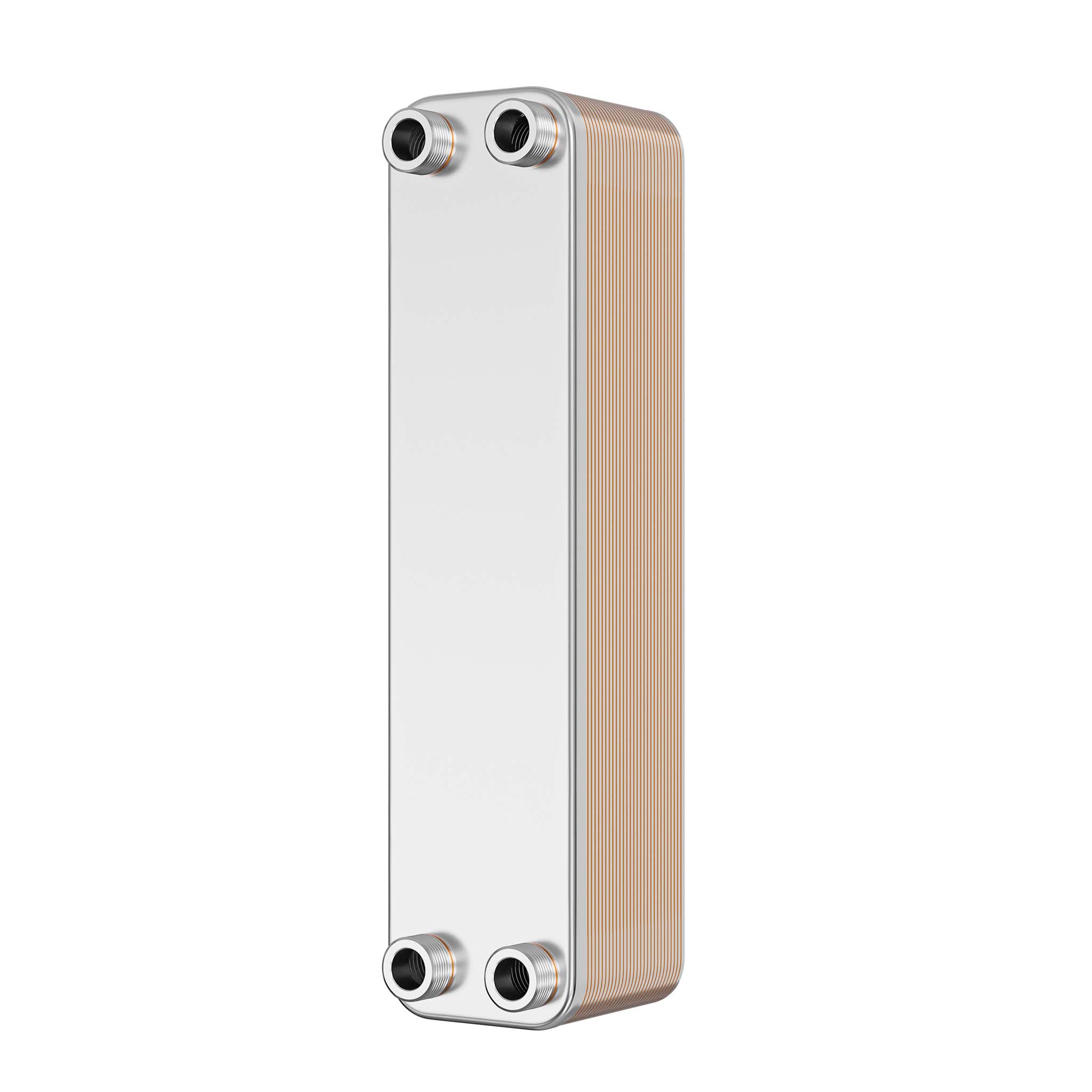

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 0.18 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 ¾″ 26.16 mm ISO-G

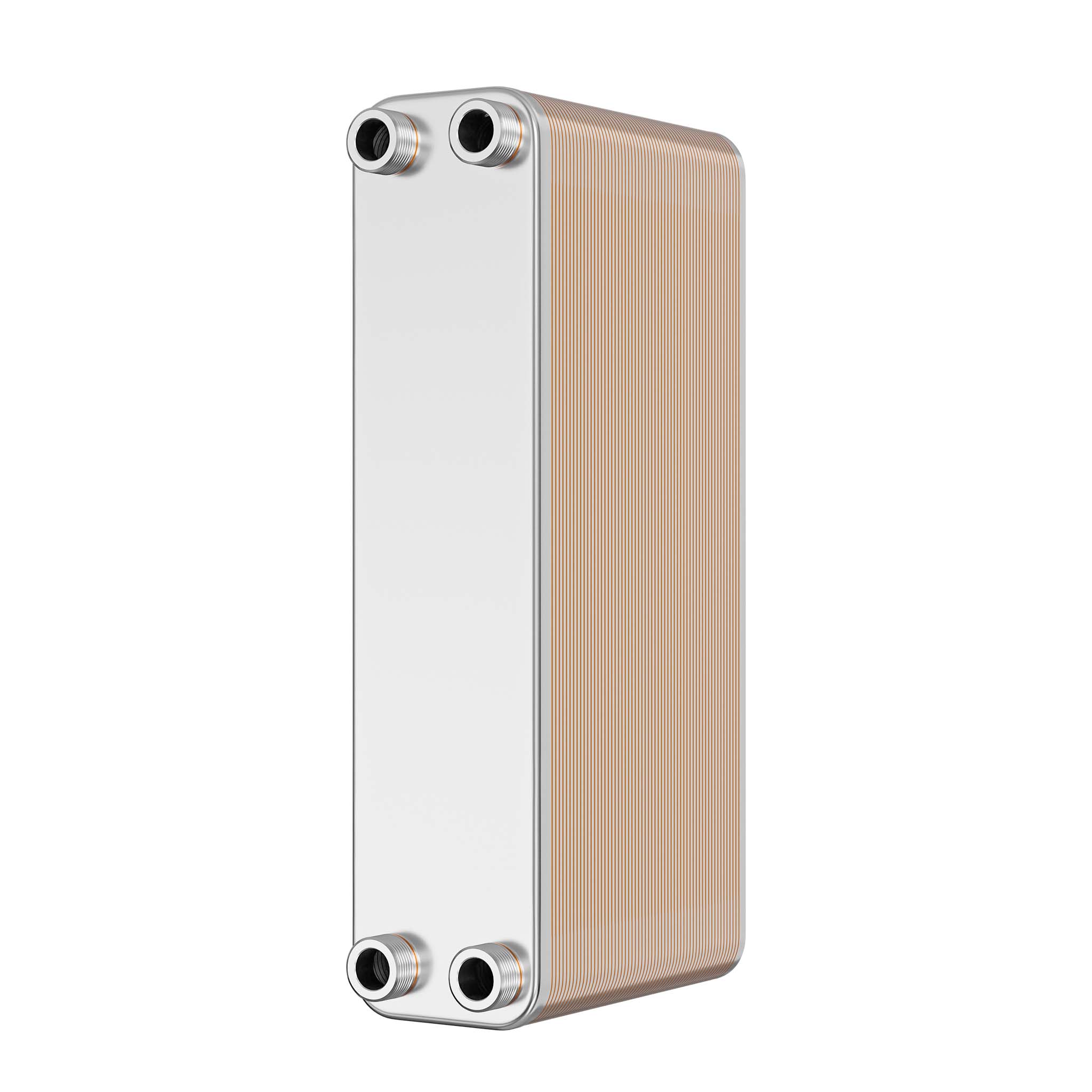

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 0.36 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 ¾″ 26.16 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 0.54 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 ¾″ 26.16 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 1.20 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 12 m³/h

• Volume per flow passage 1.50 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 22 m³/h

• Volume per flow passage 3.33 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 0.99 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 ¾″ 26.16 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 2.00 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 22 m³/h

• Volume per flow passage 6.66 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available in 48 days, delivery time 2 - 3 days

• Max. flow rate 22 m³/h

• Volume per flow passage 4.44 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 12 m³/h

• Volume per flow passage 1.00 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 12 m³/h

• Volume per flow passage 2.50 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 12 m³/h

• Volume per flow passage 2.00 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 22 m³/h

• Volume per flow passage 5.55 l

• Connections:

• F1 & F3 ½″ 32.89 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 1.08 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 ¾″ 26.16 mm ISO-G

Available, delivery time: 2 - 3 days

• Max. flow rate 4 m³/h

• Volume per flow passage 1.60 l

• Connections:

• F1 & F3 ½″ 20.67 mm ISO-G

• F2 & F4 1″ 32.89 mm ISO-G