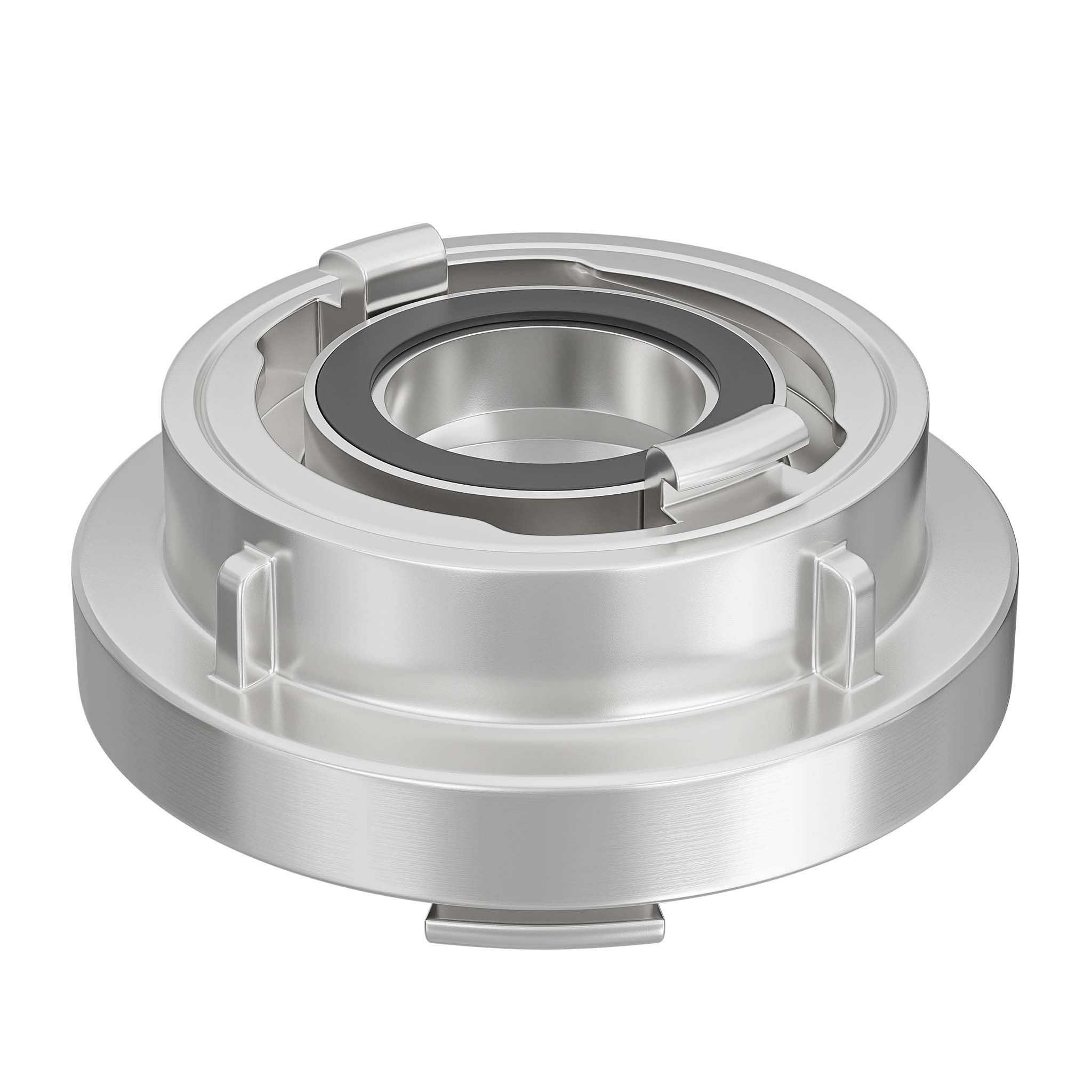

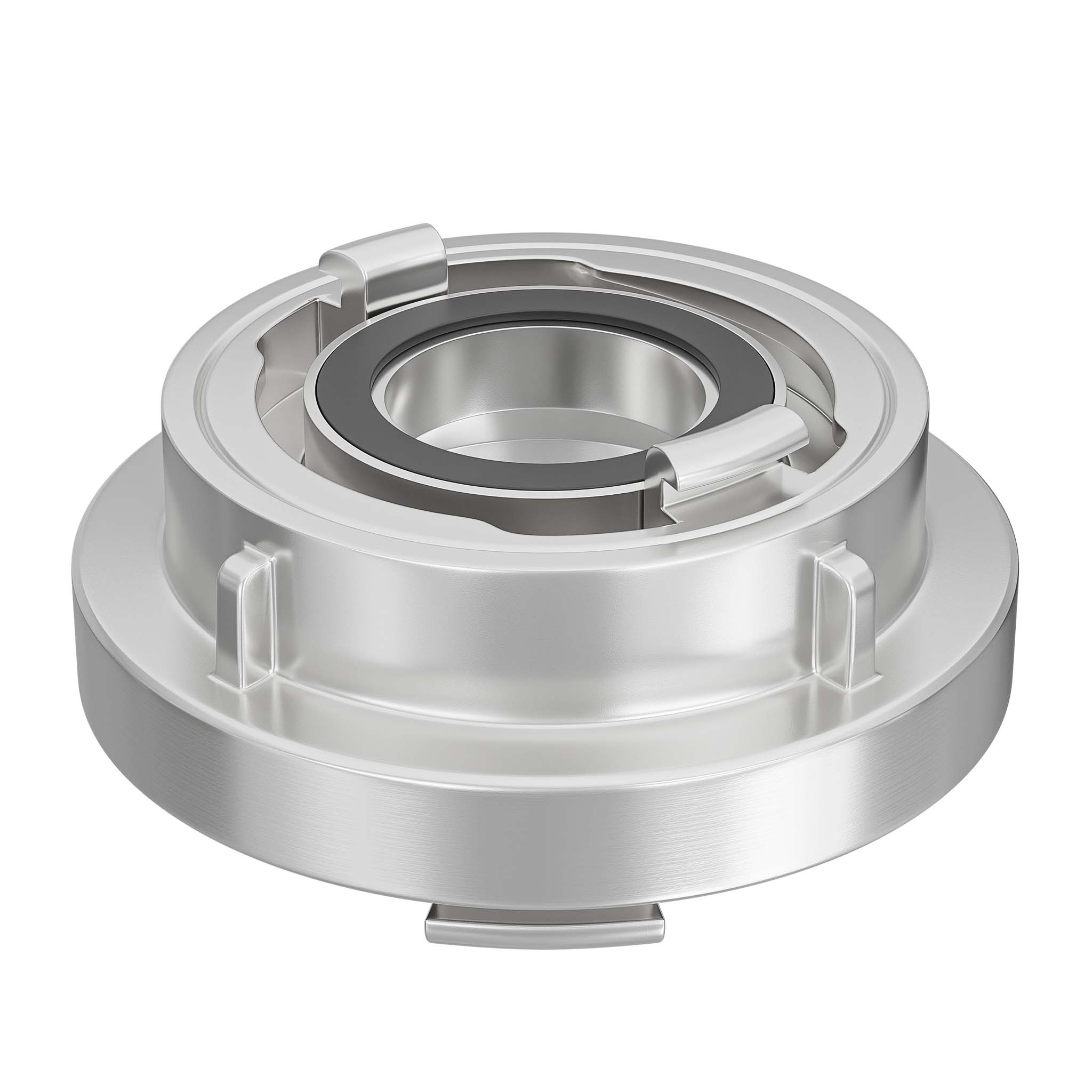

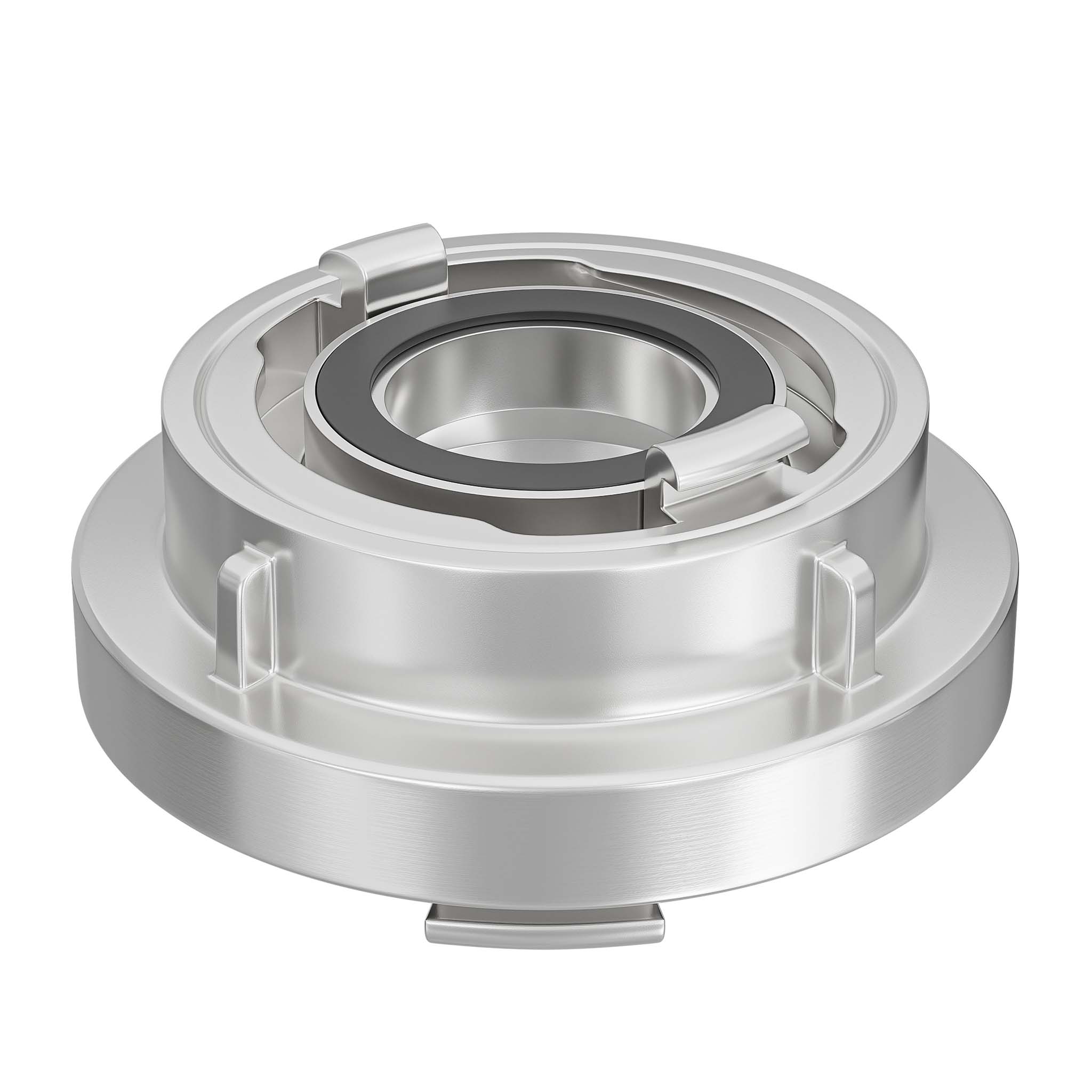

Hose Connectors & Quick Couplings

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

Available, delivery time: 2 - 3 days

• A/110 / B/75 / C/52

Available, delivery time: 2 - 3 days

• 89mm/ 3"X3" BSP

• for 89mm Hoses

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

Available, delivery time: 2 - 3 days

• With long hose nozzle

• Pressure range: 8–10 bar

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

• Coupling adapter with female thread

Available, delivery time: 2 - 3 days

• C/52 / B/75

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

• Coupling adapter with male thread

Available, delivery time: 2 - 3 days

• 75mm / 3"X2.5"BSP

• Pressure range: 8-10 bar

• Coupling adapter with female thread

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

Available, delivery time: 2 - 3 days

• With long hose nozzle

• Pressure range: 8–10 bar

Available, delivery time: 2 - 3 days

• With long connection piece

• Pressure range: 8-10 bar

Available, delivery time: 2 - 3 days

• Pressure range 8–10 bar

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

• Coupling adapter with male thread

Available, delivery time: 2 - 3 days

• Pressure range: 8-10 bar

• Coupling adapter with female thread